Vibration Monitoring Market worth over $2bn by 2026

Published Date: May 2020

Vibration Monitoring Market size is set to surpass USD 2 billion by 2026, according to a new research report by Global Market Insights Inc.

The integration of advanced technologies, such as artificial intelligence, will boost the market growth. These monitoring systems through AI modules allow users to track low cost assets in factories, such as rollers and bearings, and aid in the prediction motor or equipment failure. Also, through AI, thousands of motors and equipment can be monitored in real time concurrently, determining the issue in scalability. The companies are focusing on integrating AI into their component offerings to gain a high market share.

Software segment is gaining traction in the market due to rising focus of industry leaders to integrate smart manufacturing

Get more details on this report - Request Free Sample PDF

The software segment in the vibration monitoring market is likely to witness a growth rate of around 4% till 2026. The growth is attributed to increasing focus of companies on integrating the smart manufacturing process. Software components add an option to further simplify the exchange of data with automation assets, control systems in smart manufacturing, and IIoT devices. They have the capability to integrate high quality monitoring of data with machine learning and big data analytics to deliver more accurate prediction and sharp analysis.

Easy readability display will propel the market demand for portable vibration monitoring

The portable vibration monitoring process segment grew at a CAGR of over 4% and held a market share of around 35% in 2019. It provides the ability to gather vibration data at various points of the machine Therefore, it enables the predictive maintenance of equipment and is cost effective by reducing operation failure. This is likely to drive the demand and create market opportunities for players to develop a new portable vibration monitoring system.

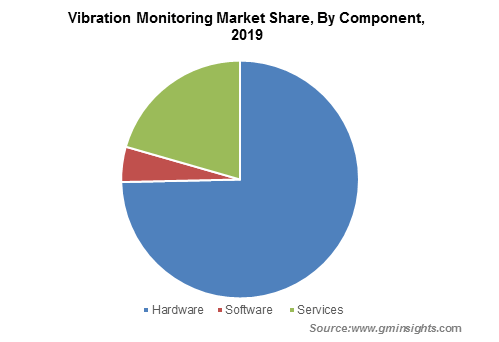

Browse key industry insights spread across 190 pages with 221 market data tables and 26 figures & charts from the report, “Vibration Monitoring Market Size By Component (Hardware, Software, Services), By Monitoring Process (Online Portable), By System (Embedded, Vibration Analyzer, Vibration Meter), By Application (Oil & Gas, Energy & Power, Metals & Mining, Chemical, Automotive, Food & Beverages), Industry Analysis Report, Regional Outlook, Application Potential, Competitive Market Share & Forecast, 2020 – 2026” in detail along with the table of contents:

https://www.gminsights.com/industry-analysis/vibration-monitoring-market

Surging demand for predictive maintenance to serve as growth driver for vibration analyzer demand

The vibration analyzer segment accounted for over 20% market share in 2019 and will witness a substantial growth rate from 2020 to 2026 on account of its ability to identify faults in machines, localize affected component, and optimize spare parts in logistics. The failure identifying capability of vibration analyzer is boosting its market demand in industries with high investments such as oil & gas, automotive, aerospace & defense, among others.

The rising awareness toward predictive maintenance to ensure proper functioning of machines will accelerate market growth for vibration analyzers. In June 2019, Embraer introduced a cloud system, IKON to store and analyze high volume of data for predictive maintenance in the aircraft sector. This leads market players to introduce new component offerings to gain a competitive edge in the market.

Increasing penetration of data centers is laying a significant impact on North America

The North America vibration monitoring market accounted for 35% share in 2019 and is expected to exhibit around 5% growth between 2020 and 2026 The region is characterized by the presence of various oil refineries and the rising domestic production of oil and natural gas in the U.S., creating high growth opportunity for the industry.

According to the U.S. Energy Information Administration, in 2019, the U.S. crude oil production grew by 11% and accounted for 12.23 million barrels per day, in comparison with 10.99 million barrels in 2018. This increase in production will require continuous monitoring of machinery to reduce the chances of system failure, driving the market.

Some of the prominent players in the market include EMERSON ELECTRIC, GENERAL ELECTRIC, Honeywell International Inc, National Instruments, AB SKF, Rockwell Automation, Inc, Meggitt, Analog Devices, Inc, among others. These companies are continuously focusing on new strategic acquisitions and merger strategies to enhance their component offerings and gain competitiveness in the market.

In October 2019, Analog Devices Inc., announced the acquisition of Test Motor, which is engaged in offering predictive maintenance for generator and electric motors. Through this acquisition, the company will expand its offerings for condition monitoring solutions. Also, the acquisition will help the company to accelerate its OtoSense startup group that develops sensing interpretation solution that recognizes vibration and sound, which are used to identify fault and potential problem in factory machines.

Preeti Wadhwani, Prasenjit Saha