Home > Chemicals & Materials > Paints and Coatings > Specialty Coatings > Thermal Spray Coating Market

Thermal Spray Coating Market Analysis

- Report ID: GMI1347

- Published Date: Feb 2018

- Report Format: PDF

Thermal Spray Coating Market Analysis

Metal is estimated to hold over 30% share in 2016. Growing need to protect bridges, large steel structures, offshore oil platforms, and deck from corrosion as well as to provide strong adhesion are key factors driving the metal-based flame spray coatings demand. These materials are mainly used as finishing and engineering coatings in various industries including automotive and healthcare. Finishing coating is further utilized as an anti-corrosion or decorative material, whereas engineering solutions are further utilized as wear-resistant and thermal barrier protection.

Ceramic materials segment in thermal spray coating market is anticipated to exceed USD 5 billion by 2024. Excellent adhesion, hardness, high corrosion resistance & thermal barrier are key properties fueling product scope particularly from diesel engine pistons, automotive valves & cylinders. Early adoption of ceramic products in aerospace engine systems, turbine blades and flame tubes due to high heat resistance has enhanced product penetration.

Benefits, such as low density, high melting point, superior oxidation, high thermal conductivity, and hot corrosion resistance, are driving the intermetallic materials demand in steam generators and coal-fired gas turbines. Polymers are observing a significant attention from automotive, petrochemical, and aerospace & defense industries. These materials are applied to protect the surface from corrosion, humidity, and harsh chemical environments.

Combustion flame is expected to generate demand over 600 kilo tons by 2024. High adoption in repairs of mining and oil & gas industry due to its suitability will drive the thermal spray coating market . Rising demand from reconditioning pumps, worn conveyor screw, and steel blowers will propel the business growth. Factors such as high bond strength and uniform surface finishing will support product application scope over forecast period.

Electric energy process will witness growth over 6.5% in terms of revenue up to 2024. High spraying capacity in terms of larger dimension coverage particularly for structural substrates will drive electric process demand. Increasing adoption of electric based process for protecting piston rings, tube seams, boiler walls, capacitors and large infrastructures will propel the thermal spray coatings market outlook.

The plasma process in thermal spray coating market is projected to witness the highest gains due to its multi-functionality with the various materials, including metals and ceramics. The process is widely applied in jet engines owing to its prevention against high temperature of the combustion gases. Also, the process is gaining attention due to the denser, cleaner, and stronger properties offered by it.

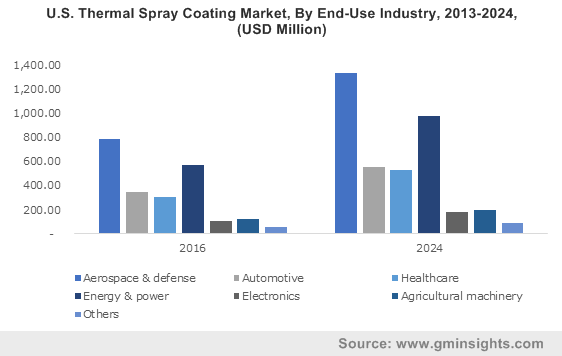

Aerospace & defense sector was worth more than 2.5 billion in 2016. Rising demand for commercial, military and general aviation due to increasing consumer spending on travelling and transportation will drive the thermal spray coating market size. As per analysis, global annual air traffic increased by 4.5% in 2017. It is the foremost industry, which has adopted thermal spray coatings completely in its manufacturing process.

The requirement to run components at the optimum level is driving the market demand. Efficient maintenance quality standards, reliability and durability along with cost-effective properties have enhanced product scope in aerospace & defense applications.

Automotive sector will witness growth over 8% through 2024. Maintenance of high-quality components, durability, and reliability is driving the product demand. Enhancing the low-cost base material life cycle through advanced functional surfaces has become important in the automotive sector. The profit margins are low, and the optimum cost has become a significant factor in the automotive industry, influencing thermal spray coating market growth.

Rising need to have biocompatible and corrosion-resistant implants is driving demand in the healthcare industry. Thermal sprayed hydroxylapatite was the foremost joint treated with an artificial bone material. It is also used in the healthcare industry to prevent RFI/EMI between medical equipment.

North America dominated the industry in terms of revenue and generated $2.5 billion business in 2016. Necessity to attain cost optimization in aviation & defense and energy & power industries are key factors driving regional demand.

Improved aircraft performance at competitive costs while meeting all the regulatory guidelines has positively influenced the thermal spray coatings market. In addition, industry practices to limit hard chrome plating usage will support product penetration over forecast period. Aerospace is one of the lucrative industries in the U.S. The sector contributed around USD 145 billion export sales to the country’s economy.

Asia Pacific is expected to witness growth over 8.5% through 2024. Growth in automotive production along with the increased supply of electronic equipment will drive the regional demand. Cost-effectiveness is one of the major reasons fueling product demand. Increasing consumer need for low weight components and customized designs is another key factor driving thermal spray coatings market.

As the region is the hub of manufacturing and exportation of components and electronics. Thus, the regional manufacturers must meet international guidelines to export goods, which will drive the demand for high-quality and environment-friendly coated products. In 2016, Asia Pacific accounted for 50% of the global vehicle production and was one of the major exporters to the American and European automotive business.