Summary

Table of Content

Refractories Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Refractories Market Size

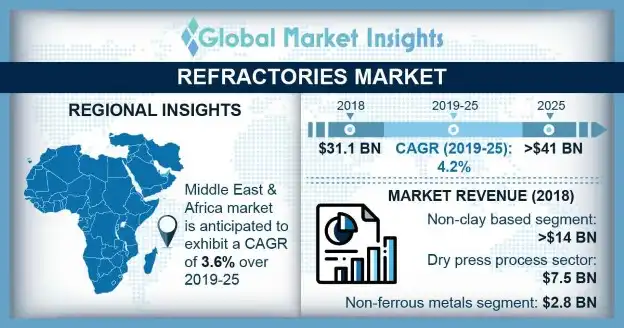

Refractories Market Size was over USD 30 Billion in 2018 and will witness a CAGR of more than 4% between 2019 and 2025.

To get key market trends

Strong product demand from aerospace, electrical, automotive, glass, cement industries is expected to drive refractories market size globally. It can withstand extreme temperature which is required for modern manufacturing. Being heat-resistant than most of the other metals, they are used for lining hot surfaces found inside many industrial processes. Refractories is available in different shapes and sizes; they are generally pressed, molded or produced in interlocking shapes and wedges for its use in floors and walls.

Growing iron and steel industry will have a positive outlook on the market for projected period of time. For instance, the global steel production was 1,433 million tons in 2010 and increased to 1,808 million tons by 2018. The rapid growth of iron and steel industry can be attributed to growing infrastructural projects mainly in emerging economies of Asia Pacific. Moreover, with rising demand for more energy efficient technique in steel making the demand for refractories is estimated to grow in the near future. Emission of volatile organic compounds (VOCs) and its environmental concerns along with health and safety issues related with refractories is likely to hinder the overall refractories market share in forecast time period. However, increasing efficiency of baghouses and fabric filters to control VOC emissions, will have a positive outlook for the market size by 2025.

Refractories Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2018 |

| Market Size in 2018 | 30 Billion (USD) |

| Forecast Period 2019 - 2025 CAGR | 4% |

| Market Size in 2025 | 41 Billion (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

Refractories Market Analysis

Refractories market based on form is segmented into bricks & shapes, monolithic and others. Bricks & shapes accounted for more than 55% of the total industry share in 2018. The bricks & shapes refractories are also called performed refractories and are basically utilized to form the floor tiles, arches and walls of various extreme temperature process equipment. Refractories shape and production depends primarily on the structure and size of furnaces or other services where refractories products are utilized. Only iron blast furnace needs refractories brick of varied shapes and sizes. However, other lining works are composed of standard refractories already available in the market. Special refractories shapes are developed to fulfill the specific lining criteria of each furnace such as stopper heads, arch tiles or over shapes.

Based on composition the market is classified into clay-based and nonclay-based refractories products. Clay based refractories market generated revenue close to USD 16 billion in 2018. Clay based refractories include mullite ceramics, fire clays, etc. They are generally produced as monolithics, preformed brick and also materials which are composed and solidified on-site. Clay based refractories also helps in developing light weight refractories in the form of blankets, vacuum cast shapes and fiberboards.

Based on type the market is divided into acidic, basic and neutral. Neutral type segment accounted close to 60% of the total industry share in 2018. Neutral refractories cannot be attacked by acid or basic slags and are thus the most preferred product type. Neutral refractories include graphite, chromites, zirconium carbide, silicon carbide, etc. While, graphite is less reactive than other materials, it is also used in metallurgical furnaces where oxidation can be controlled.

Refractories market based on manufacturing process is segmented into unformed, dry press, fused formed, fused cast and hand molded. Fused cast market size in terms of revenue was over USD 4 billion in 2018. The raw materials necessary for refractories in each manufacturing process are oxidized prior to melting by treating it with heat, to reduce oxygen content required for oxidizing molten refractories.

Refractories market based on end-user is segmented into iron & steel, non-metallic materials, non-ferrous metals and others. Iron & steel market size accounted close to 65% of the total industry share in 2018. Iron and steel requires refractories to be used in blast furnaces, basic oxygen making steel vessels, process gas heaters, troughs, electric arc furnace, torpedo ladles, etc. China has well established iron and steel market which represents as an important factor driving refractories production in the country.

Learn more about the key segments shaping this market

Learn more about the key segments shaping this market

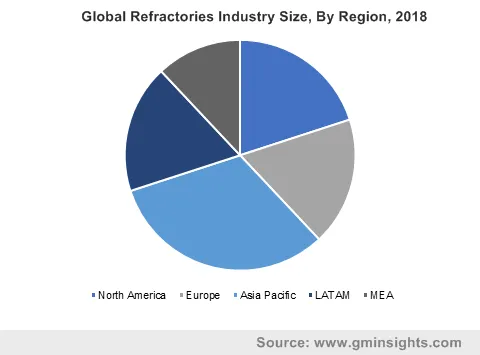

Asia Pacific led the overall market share and is likely to exhibit gains close to 4.0% CAGR by 2025. The growth of APAC market is largely driven by the growing production and research and development centers in the region. Japan, India and China are the leading contributors in iron & steel, non-ferrous and glass industries. Various industries are growing due to growing per capita expenditure of the population and rising urbanization in the region. These factors are anticipated to drive Asia Pacific refractories market size by 2025.

Refractories Market Share

Refractories market share is fragmented due to presence of many small and large scale manufacturers. Prominent market share contributors are:

- RHI Magnesita

- Krosaki Harima Corporation

- Vesuvius PLC

- Shinagawa refractories Co., Ltd

- Saint-Gobain

- Morgan Advanced Materials

- CoorsTek Inc

- HarbisonWalker International

- Imerys

Most of these industry players are focusing their R&D activities to develop new products with improved properties, to gain more market share. For instance, Imerys subsidiary Calderys recently announced its international expansion into Indonesia and Japan. Calderys signed a strategic joint venture agreement with PT Indoporlen an Indonesian refractories manufacturers and has also acquired Tokai Ceramics Co., Ltd. of Japan.

Industry Background

Refractories are materials which have high melting point and can maintain structural properties at very high temperature. Based on forms they are available are bricks & shapes, monolithics and others. Refractories products are clay based which contains high alumina, fire clays and mullite ceramics content and nonclay based. Depending upon on slag they are segmented into acidic, basic and neutral refractories. The manufacturing process for refractories include dry press process, unformed, fused cast, formed, hand molded. They have a wide ranging application in iron & steel industry, non-metallic materials such as glass, cement, lime and ceramics, solar panels, etc. They are also utilized in production of non-ferrous metals which includes aluminum, copper, etc. Escalating iron & steel demand in Asia Pacific, Latin America and the Middle East on account of escalating building & construction industry will complement industry growth in the coming years.

Frequently Asked Question(FAQ) :

How much size did the global refractories market register in 2018?

refractories market was valued at USD 30 billion in 2018.

What kind of growth will global refractories industry size observe during the forecast timeframe?

Expected crcr that refractories market is estimated to register is 4% over 2019-2025.

Refractories Market Scope

Related Reports