Home > Chemicals & Materials > Advanced Materials > Functional Materials > Purging Compound Market

Purging Compound Market Analysis

- Report ID: GMI2145

- Published Date: Oct 2017

- Report Format: PDF

Purging Compound Market Analysis

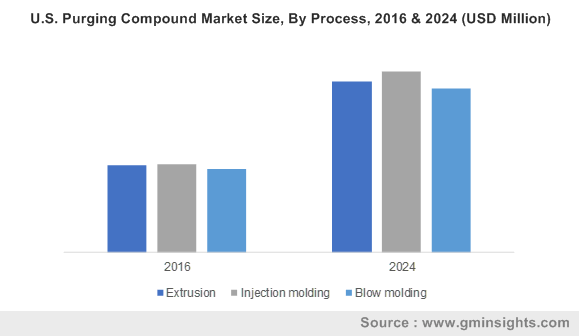

Extrusion is projected to witness growth rate 7% through 2024. High product requirement for extrusion due to advantages including faster color & material changes and ease in carbon removal will enhance industry. Improved processing among comprehensive thermoplastics including GPPS, PP, PC, PA and ABS is the key factor supporting the purging compound market share.

Injection molding process segment was worth of USD 109 million in 2016. Injection molding extensively use these compounds while changing resin, color or removal of black specks. Easy color changeability without demounting equipment, thus gaining optimum results are key factors fueling product demand. High cleaning accuracy in several engineering components will further enhance product penetration.

Blow molding has been observing significant growth in the industry. Increasing demand for the mass production of several injection molded components from end-use industries including automotive will enhance the purging compound market share.

Mechanical purging is projected to surpass USD 400 million by 2024. Efficient removal of polymer deposit by utilizing high viscosity plastics from screws and barrels will enhance the product demand. Increasing demand for plastic processing units due to manufacturing industry expansion will drive the purging compound market growth.

Chemical/foaming was valued over USD 90 million in 2016 as it is considered as the most common product used in plastic processing apparatus. High foldability rate making the scrap to repeatedly be used to remould parts is expected to improve product usability.

Liquid form is anticipated to observe a growth rate of more than 7.5% through 2024 due to increasing demand for the removal of all thermoplastics. The form is extremely effective for resin to resin and color to color changes to provide easy, quick, safe and cost-effective conventional processing. In addition, unique form properties including non-requirement of soaking and cracked acrylic resin inventory will drive the overall global purging compound market.

Granule form segment was worth of over USD 250 million in 2016. The form significantly limits the removal of certain contaminants including carbon build up from the extruder. It is effective for the treatment of several chemicals that are in a granule structure of ultra-high purity purges. Further, the form evolves as a crucial part in production of specialized cleansing materials and thereby boosting global purging compound market.

Automotive is anticipated to maintain its dominance over the forecast period owing to extensive adoption of lightweight and sustainable plastic materials in the form of equipment, films and fasteners components. Automotive industry will be valued over USD 130 million by 2024. Exclusive partnerships between OEMs and product manufacturers will benefit in industrial development in terms of supply chain efficiency. Furthermore, increasing initiatives by automakers to accommodate growing senior driver population by including safety features will boost the global purging compound market revenue.

Electronics sector held 8% of volume share in 2016. These product mixtures are used in a wide array of electronics applications including switches, sockets, enclosures, housings and semiconductors. Growing necessity for heat resistance, flame retardancy and enhanced serviceability in producing materials will drive the purging compound market segment.

North America registered over USD 100 million in 2016 with largest production share over the forecast period. This share is primarily credited to the large base of plastic processing units in the region. Increasing demand for plastics processing equipment is also expected to drive global purging compound market growth.

Asia Pacific is anticipated to grow at a rate over 7% from 2017 to 2024. The growth will be attributed to rapid industrialization contributing towards expansion of several industries including food & beverage, construction, automotive, petrochemicals and chemicals. As these composites is gradually used by these industries to decrease machine downtime and expand manufacturing efficiency, the growth of the end-use industries will continue to boost the global purging compound market sales.