Home > Industrial Machinery > Industrial Equipment > Tools > Pulp Molding Machines Market

Pulp Molding Machines Market Analysis

- Report ID: GMI4794

- Published Date: Aug 2020

- Report Format: PDF

Pulp Molding Machines Market Analysis

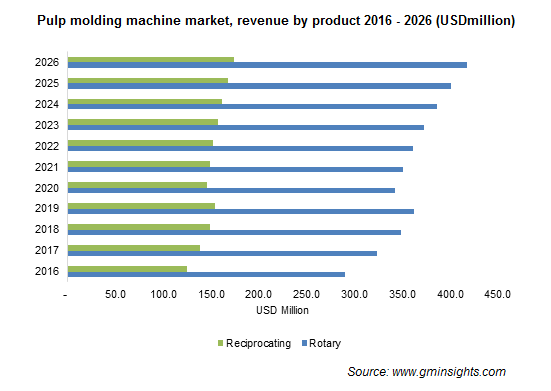

Rotary machines generated a revenue more than USD 350 million in 2019. Rotary pulp molding machines have the capability of manufacturing both large and small molded units. These molding units have simple functionality and reasonable expenses, making them appropriate for several applications. Moreover, rotary machines have the ability to alter heavy amounts of waste and recycled paper to various molded pulp products used in an array of industries.

Automatic machines are expected to grow at a CAGR over 3.5% by 2026. An automatic molding unit can perform definite tasks without being operated by a specialized person or employee. These machines possess automatic dry system, high rate of mold handling, and are easier to operate.

The demand for automatic molding units is estimated to grow profoundly as many end-use industries are requiring largely automated machines that enhance their production. Many producers of pulp molding machines are concentrating on manufacturing highly efficient, sophisticated yet easy to operate machines.

Molding machines with a capacity less than 1,500 units/hour will register a volume share over 20% in 2026. This series of machines is majorly preferable for small-scale industries, which can offer a low cost of capital venture. Its production capacity generally ranges from 700 pieces to 1,500 molded pulp pieces per hour, intaking minimum molding dies.

Furthermore, the integrated pulping structure can be applied to save construction expenses and plant space. Also, the assembly line here only requires three to six workers, resulting in minimum labor cost.

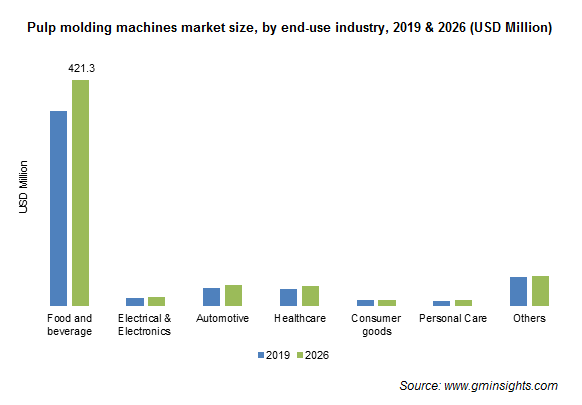

The food & beverage sector will record the highest revenue share of close to 70% in 2026. Strong advancements in the food industry are driving the development of sub-sectors such as foodservice packaging activities. The swelling number of quick service eateries around the world has been powering the consumption for foodservice disposables.

These restaurants are lessening their efforts to maintain and clean the used plates or trays. This has expanded the need for low-cost, single-use disposable packages, directly advancing the pulp molding machines market share in the near future.

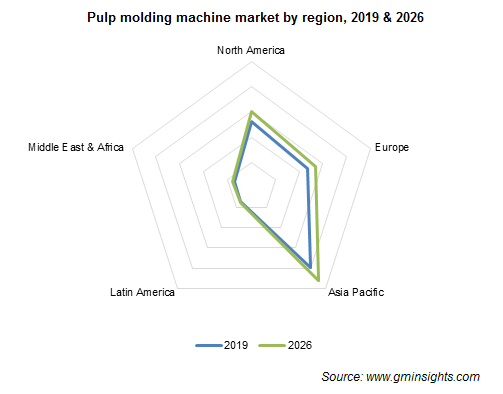

The industry size in Asia Pacific is expected to witness the fastest growing at a CAGR around 3.5% by 2026. The robust development in the region is attributed to the escalating usage of disposable packaging solutions. Presently, the Asian countries are shifting their preference toward sustainable materials in food and consumer products packaging, supporting the enhancement in the molded pulp machines market.