Home > Chemicals & Materials > Specialty Chemicals > Custom Synthesis > Phenol Derivatives Market

Phenol Derivatives Market Analysis

- Report ID: GMI2002

- Published Date: Oct 2019

- Report Format: PDF

Phenol Derivatives Market Analysis

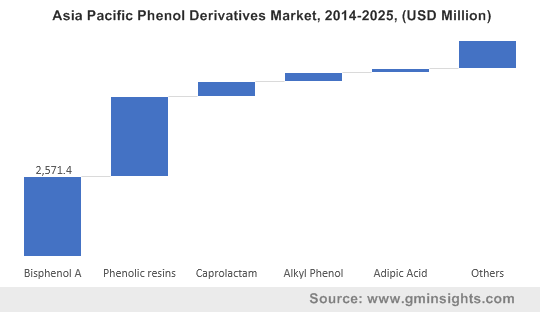

Phenolic resins constitute a major share in phenol derivatives market. The product is largely used as a base material for the synthesis of Bakelite, a synthetic plastic known for its insulation property. It is also extensively used for manufacturing molded products such as laboratory countertops, billiard balls and as adhesives and coatings. The resin is largely used across automotive, furniture, construction, electronic and electrical as a precursor or as an additive. Positive prospects in decorative laminates and the wood-adhesives industry are likely to build a strong support platform for phenolic resins over the forecast period.

Phenolic resins for commercial applications are available in customized additive and filler combinations, for example, with fiberglass and carbon fiber reinforcement, tailored to the requirements of specific end-use industries. The increasing use of materials, which carry fire retardant, heat-resistant, and anti-corrosive properties for the industrial purpose acts as a major driving force in the market. Owing to its thermostable properties, phenolic resins have gained increased penetration where hazards of fire, smoke, and toxic release are prominent.

Bisphenol is used as a key raw material in formulating polycarbonate which is extensively used throughout the automotive industry. Several components of automobiles such as tail lamps, headlights, sunroofs, windows and various other car parts consists of polycarbonate material. Also, phenolic resin, one of the key derivative is widely used for brake linings, insulation foams and composites for automotive industry.

Caprolactam derived from phenol is used to formulate engineering resins, nylon 6 fibers and films. The product demand is increasing across automotive sector as engineering resin is rapidly gaining traction as it is replacing metals for constructing outdoor frames. This has reduced weights of vehicles owing to which fuel efficiency and performance has improved. These applications of phenol cater to growing automobile industry need for light weight vehicles with higher fuel efficiency and performance.

Asia pacific is the largest phenol derivatives market and accounted for over 45% market share in 2018. Major economies of the region such as China, India, Japan, and Thailand are seeing high growth rate owing to factors such as duty rationalization for raw materials, tax incentives for R&D investments, and improved infrastructure. Continuous government support via numerous revised regulations & policies along with the rapid development of the transportation of infrastructure will enhance the application scope in the market.

Surplus amount of investments from foreign investors is being invested across petroleum, chemicals, and petrochemical industries which will drive the impelling market across this region. Factors such as presence of abundance of raw materials for producing phenol and its derivatives and expansion of manufacturing unit are further likely to support the phenol derivatives market advancement.