Home > Chemicals & Materials > Advanced Materials > Functional Materials > Phase Change Materials Market

Phase Change Materials Market Analysis

- Report ID: GMI2241

- Published Date: Aug 2020

- Report Format: PDF

Phase Change Materials Market Analysis

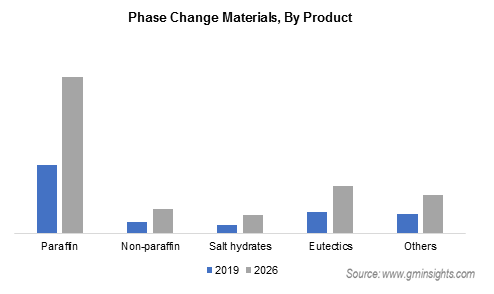

Paraffin constituted approximately 53% of the total phase change materials market share in 2019 in terms of revenue and is likely to witness a gain of 18.3% during the forecast timeframe. Paraffins show good storage density with respect to mass & melt and solidify congruently with little or no sub-cooling. Their thermal conductivity is however comparatively low. Paraffins have melting temperature ranges that are suitable for a range of applications as they possess high latent heat, have good thermal characteristics, and are chemically & thermally stable.

Paraffinic hydrocarbons are widely used in textiles than other PCMs due to their excellent characteristics such as non-corrosive, thermal & chemical stabilities, and low undercooling. Paraffins have low solubility in water; hence, are highly used in building materials and they exhibit melting enthalpies between 150 and 220 KJ/Kg.

The other phase change material market segment is projected to exhibit a CAGR of over 14.9% during the review period. Other phase change materials primarily include biobased phase change materials. They are non-toxic and are made from biodegradable raw materials. They are hydrogenated hydrocarbons that are chemically stable and can last for a longer duration. These are generally made from vegetable oils, waxes, and fruit oils. Biobased PCMs can provide price/performance characteristics that superior to paraffin PCM chemicals.

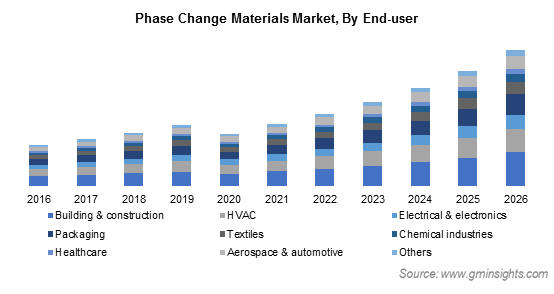

The building & construction sector held a market share of over 23% in 2019. The rising investments in research & development activities and emerging technologies in macro and microencapsulation are anticipated to create lucrative opportunities for the phase change materials market in the building & construction industry. The usage of adequate thermal energy storage systems in the building & construction sector offers high potential in energy conservation. Furthermore, PCMs are widely used in construction materials through different techniques.

Some of the most commonly used methods are immersion, direct incorporation, microencapsulation, encapsulation, and shape-stabilization. Increasing product applications in building & construction activities will spur the PCM market in the coming years.

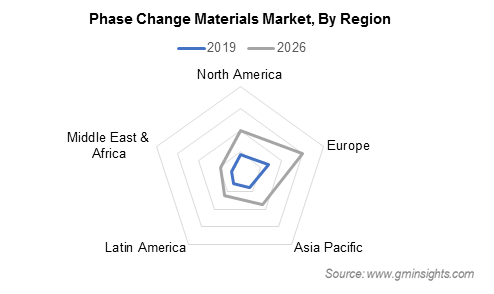

Europe held the largest share of 30% in the global PCM market in 2019. It is primarily due to advanced construction practices in Europe and the growing demand for HVAC systems in residential houses. The integration of phase change materials into heating systems and ventilation will considerably affect the room temperature. Europe experiences cold weather conditions; hence, good HVAC systems are needed all around the year, which will eventually create demand for phase change materials.