Home > Packaging > Packaging Materials > Paper and Cardboard Packaging > Paperboard Packaging Market

Paperboard Packaging Market Analysis

- Report ID: GMI2060

- Published Date: Oct 2020

- Report Format: PDF

Paperboard Packaging Market Analysis

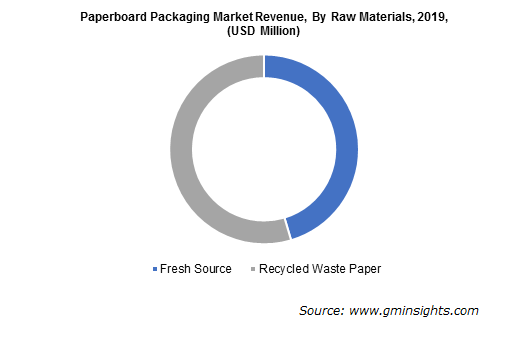

In 2019, recycling segment held over 50% share in paperboard packaging market. A key advantage of paper and paper board is that it can be recycled as fiber and used to develop new paperboard products. Nearly 50% of world’s fibers for paper making are supplied through paper recycling. Increasing concerns relating to deforestation and the sinking forest cover across the globe have resulted in paperboard manufacturers opting for recycled sources.

Strong upward growth trajectory of paper recycling is expected to propel the paperboard packaging market segment over the forecast period. As recycling of paper causes its quality to deteriorate over time, fresh source needs to be added in proportion to keep the fiber strength to the mark.

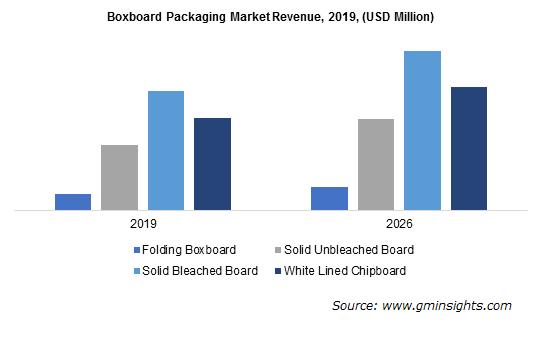

Folding boxboard segment will witness over 3% CAGR in boxboard packaging product segment by 2026. Folding boxboard is a grade of boxboard that can be bent without fracturing. It is manufactured from multiple layers of mechanical & chemical pulps. Folding boxboards are low density boards with high stiffness. These can be used to package beauty products, frozen foods, and pharmaceuticals.

Solid Unbleached Board (SUB) is a grade of boxboard that is made up of unbleached chemical pulp. It is usually available with two or three layers of pigment coatings. Recycled fibers can also be used instead of unbleached chemical pulp. Solid unbleached boards are generally used to package beverage carriers, detergents, toys, and others.

Solid Bleached Board (SBB) is a virgin grade of boxboard. It is manufactured from bleached chemical pulp and usually has synthetic or mineral coatings. SBB is a medium density boxboard; hence, it can be used for graphical or printed packaging applications. It is primarily used for flavor or aroma-sensitive products such as cosmetics, and cigarettes.

White lined chipboard is manufactured from layers of waste papers and recycled fibers. It is generally available with two to three layers of coatings on both the sides. White lined chipboard contains recycled materials; thus, direct contact with food leads to health issues.

Food & beverages have emerged as the key application segment in paperboard packaging market share, accounting for over 50% share in 2019.The application segment includes packaging of frozen foods, alcoholic and non-alcoholic beverages, candies, dairy products, fast foods, and fresh fruits & vegetables. The strong growth of this segment is attributable to excellent operational characteristics of paperboard packaging. This packaging is safe for food contact, can operate over a wide range of temperatures, and helps in maintaining organoleptic properties for a long period of time.

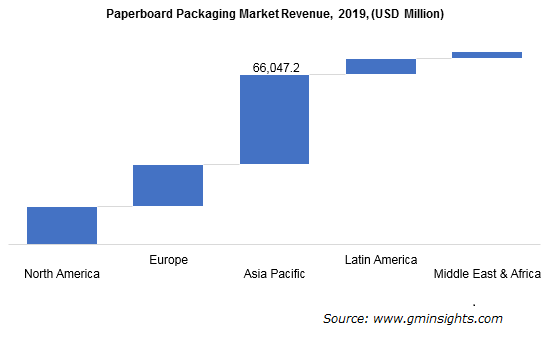

Asia Pacific paperboard packaging market will generate over USD 65 Billion in 2019. Globalization has led to an increase in trade activities in countries such as China, India, South Korea, and Malaysia over the past few years. Rapid urbanization, strong economic growth, and rising consumption of packaged food products are some of the major factors contributing to the growth of the packaging market in the region.

The highly competitive environment is expected to generate opportunities for the future market growth. Moreover, favorable trends associated with cosmetics and medical sectors will drive the paperboard packaging market sales within this region.