Summary

Table of Content

North America Precision Gearbox Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

North America Precision Gearbox Market Size

NA Precision Gearbox Market size was worth over USD 371 million in 2016 and its demand is projected to cross 968.9 thousand units in 2024.

To get key market trends

The industry is expected to witness a robust growth over the forecast time frame owing to the continuous investment in innovative machinery to provide superior accuracy. Rising need for operational cost reduction in manufacturing plants will foster the business demand. The cost reduction can be attained by minimizing the raw material wastage and production workflow errors. A widescale use of precision gearboxes in diverse end markets across the globe will escalate the industry growth from 2017 to 2024.

High adoption rate of this product is witnessed over the coming years owing to high investments for the development of technologically-advanced production facilities. Rising automation demand in machine tools, food beverage & tobacco industry, materials handling and packaging applications will support the NA precision gearbox market size from 2017 to 2024. High usage in robotics industry will further support the industry growth. Automation in manufacturing industry contributes to the extensive competitiveness and offers immense potential by assuring value creation over excessive labour costs according to the international standards.

North America Precision Gearbox Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2016 |

| Market Size in 2016 | 371 Million (USD) |

| Forecast Period 2017 - 2024 CAGR | 5% |

| Market Size in 2024 | 556 Million (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

North America Precision Gearbox Market Analysis

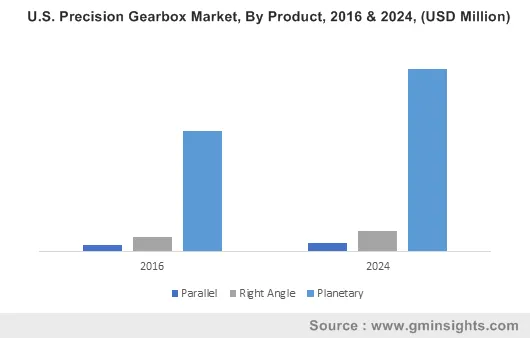

NA precision gearbox market from parallel was valued at USD 16.7 million in 2016 and will exhibit 4.0% CAGR up to 2024. Parallel gearbox, also known as coaxial gearbox, has input and output shaft parallel or in line to each other. These are mainly useful owing to their compact design, occupying less space.

Right angle gearbox acquired nearly 10% of total market share in 2016. They are used for applications with output and drive shaft inclined at 90 degrees with each other. Applications requiring inclined shaft prefer right angle precision gearbox. Limited installation space and compact design are the key factors boosting the product growth. Along with this, right angle precision gearbox can be combined with other gearboxes adding advantages to the product. The combination of the right-angle precision gearbox with other precision gearbox provides an added advantage in the installation of applications. The key disadvantages of the product are complex design and low torque transmission ratio.

Carbon steel is estimated to acquire over 23% of volume share in 2024 owing to higher strength and low cost of the material. The advancement in carbon steel with a superior watertight design required by the application will boost the business demand.

Recent developments in molding and manufacturing techniques will support the plastic segment. Increasing innovations owing to lightweight applications requiring minimum lubrication will boost the overall business demand. Plastic is used for the applications requiring less power output along with low maintenance of the product. Applications in constant contact with the fluid or chemicals mainly prefer plastic gearboxes.

Automotive applications registered revenue more than USD 122 million in 2016 and is anticipated to dominate the industry over the forecast timeframe. The expansion of the automotive industry will support the business growth. The shifting consumer preference toward electric vehicles supplying optimum power and speed will boost the industry demand. The noiseless operation for the application will further stimulate the product demand.

Precision gearbox application in food industry is projected to exhibit 6% CAGR during the forecast timeframe. The expansion in packaging technology across the food industry reduces the production time and offers ease in application, driving the product demand. Tight tolerance is required between casing and gears for proper functioning and the industry players are developing products as per the application requirements.

The OEM is expected to dominate the precision gearbox market acquiring more than 84% volume share in 2024. Superior tolerance along with ease-in-installation owing to the higher precision of the product will support the product demand. Manufacturers are offering increased product range and supplemental offerings in the market. According to the application requirements, the product is required to deliver high durability, economy, efficiency, reliability, lubrication, and value. Expanding demand for the automotive, food, and healthcare applications will further enhance the product growth. Equipment requiring precise and fast indexing movement is boosting the demand for precision gearboxes. Products available in gear ratios ranging from 5:1 to 50:1 provide customized solutions for OEM applications.

U.S. precision gearbox market was valued at USD 332 million in 2016 and is expected to increase at 5.3% CAGR up to 2024. The industry growth will be fuelled by the country’s healthy economic growth, increasing individual income levels, continued industrialization efforts, manufacturing output, and innovations in vehicles. The food & beverage industry of the U.S. aims at competitive pricing coupled with sustainable production, transportation, and packaging solutions. This operational efficiency is attained by implementing automated solutions, thereby enabling producers to develop advanced products at low costs. Increasing automation needs in the country will support the industry growth in the coming years.

Market growth is estimated to be healthy in Canada. The appropriate pricing of the product with appreciable features will attract the customers’ attention. To sustain in the competition, it is vital to manage expenses related to the manufacturing and offer low-priced products. The business prospects are strongly associated with the economic activities of the country in core sectors such as mining, oil, infrastructure, and power.

North America Precision Gearbox Market Share

The precision gearbox industry in NA consists of OEMs and aftermarket suppliers competing in the marketplace with innovation, design expertise, and strong distribution channels. Some of the competitors in the market are:

- WITTENSTEIN SE

- Nuegart GmbH

- APEX Dynamics

- GAM

- CGI, Inc

- Anaheim Automation, Inc

- Onvio LLC

- Adobe Precision Gear, Inc

- REM Surface Engineering

- Amarillo Gear Service

- Matex Gears

- Auburn Gear.

Industry players are adopting long-term supply agreements with the other players to maintain the overall demand for the product along with reducing the cost involved in the supply chain. Customization as per the requirement of the application will bolster the overall industry demand for the product. Manufacturers are focusing on the cost-saving potential of the product while manufacturing and reducing the logistics cost of the product. The availability of the product, particularly on the web portals of the industry will further support the overall the precision gearbox market growth.

Industry Background

Precision gearboxes are power transmitting devices with a high performance and special construction requirements. Low backlash with variability achieved in torque and speed is the key property used in various applications. Precision gearbox is an efficient cost-cutting device adopted by OEMs to enhance their profitability. These advanced products provide flexibility with minimum backlash for an extended period of time. Rising industry players across the globe have increased the competition within the industry.

The product requires self-locking facility mainly for applications such as stairlifts, facade technologies, stage, and material handling. The requirement of reducing the cost along with energy saving trend in automobiles will boost the business growth. Superior alignment and significant versatility in the design based on the application requirements will propel the product demand. Enhanced dimensional control for the application with a superior finish of the product is mainly preferred by the end-use industries. Shifting consumer preference toward products with enhanced comfort and compact operations will further support the business growth.

The availability of after-sales services and consultation offered by the manufacturers as per the application requirements will strengthen the foothold in the market. Numerous manufacturers are accredited with standards, such as ISO/TS16949, that cover quality management system and address cost performance along with ongoing improvements. Increasing standardization in industries with demand for noiseless and highly compatible devices will boost the overall industry growth.

Frequently Asked Question(FAQ) :

What is the expected growth rate for North America precision gearbox industry share during the forecast timespan?

The industry share of North America precision gearbox is expected to grow at more than 5% CAGR between 2017 and 2024.

What was the size of the North America precision gearbox market in 2016?

The market size of North America precision gearbox was worth over USD 371 million in 2016.

North America Precision Gearbox Market Scope

Related Reports