Summary

Table of Content

Highly Reactive Polyisobutylene (HR-PIB) Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Highly Reactive Polyisobutylene Market Size

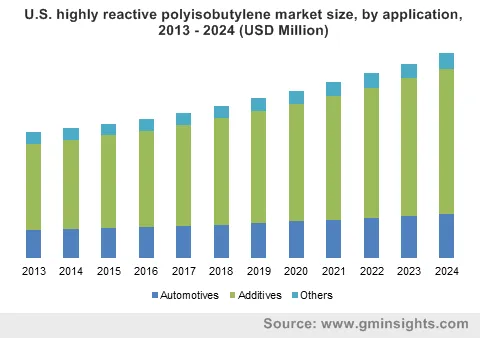

Highly Reactive Polyisobutylene (HR-PIB) Market size was more than USD 200 million in 2016 and will witness 4.7% growth during the forecast span. Rising environmental concerns which is attributed to stringent legislations formed by regulatory bodies and regional government is likely to impede market share over the projected timeframe.

For instance, product is used as a lubricant in ship engines contaminated water leading to polluting water bodies which affect aquatic life by causing death and genetic alteration in the long run. However, strong demand from automotive, construction, etc. industry will generate plentiful opportunities for highly reactive polyisobutylene market size in the near future.

To get key market trends

Product finds major application in the construction industry as adhesives & sealants owing to its tackiness and stability which makes it ideal for various hot melt pressure sensitive adhesives. Additionally, moisture resistance, high degree of elongation and good adhesion properties to multiple substrates make it useful for sealants.

The construction industry in the Middle East is likely to grow at a CAGR of over 7% which in turn will boost highly reactive polyisobutylene market size in the coming years. This is due to wide-ranging product use in adhesives and sealants in various forms for damp proofing and roof repair. For instance, adhesives are used in flooring, insulation, panel, partitions and roofing, while sealants are used in facades, fire protection and IG units, among others.

Strong product demand across automotive industry primarily in Asia Pacific has propelled highly reactive polyisobutylene market size in recent years. This is majorly attributed to increasing population along with rising socio-economic factors in the region which has been driving automotive industry and subsequently driving demand for tire & tubes industry. Product finds application in manufacturing inner liners of tires owing to its impermeable nature. It is also used to manufacture tubeless tires which are more durable and require less maintenance.

On an average, HR-PIB accounts for 15% of the total rubber content in a tire which also varies depending on the vehicle. For instance, the rubber content in a car tire varies from 3.7 kg/tire in Japan to 5.0 kg/tire in the U.S. and Germany. For commercial vehicles (CV), it varies from 9.24 kg/tire in Japan to 24.28 kg/tire in the U.K. These trends are likely to make a substantial impact on the overall highly reactive polyisobutylene market size during the forecast period.

Highly Reactive Polyisobutylene Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2016 |

| Market Size in 2016 | 200 Million (USD) |

| Forecast Period 2017 - 2024 CAGR | 4.7% |

| Market Size in 2024 | 332.3 Million (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

Highly Reactive Polyisobutylene Market Analysis

Low molecular weight for highly reactive polyisobutylene market size attained the highest industry share and is anticipated to grow at a CAGR close to 4.5% in the near future. This is majorly due to its primary application is as a reactionary intermediate such as lubricant additive manufacturing. Low molecular weight HR-PIB viscosity is approximately 225 mm2/s at 100°C. Additionally, it possesses various other value-added advantages including less char production during manufacturing and ability to improve final lubricant and fuel performance.

Learn more about the key segments shaping this market

Highly reactive polyisobutylene market size for additive is anticipated to grow at a CAGR close to 5% in the coming years. This is chiefly due to product’s detergent properties which reduce hydrocarbon and particulate emission when added to fuel. Rising need for lower emission fuels is likely to further augment product demand which in turn will help attain promising gains to highly reactive polyisobutylene market size in the coming years. It is added in small amounts to lubricating oils to help reduce oil mist generation and offer improved final product performance to the consumer and better manufacturing economics for the additive supplier.

North America highly reactive polyisobutylene market size is projected to grow at a CAGR of over 4.5% during the forecast period. This is majorly due to strong growth in the automotive, construction and medical packaging industry. Product possesses excellent features including chemical resistance and low permeability to air, moisture and gases. Henceforth, it is preferred in manufacturing a range of medical packaging applications such as serum vials, injectables, saline bottles and seals which will make noteworthy contribution to highly reactive polyisobutylene market size over the projected timespan. Product’s impermeable nature makes it preferable for manufacturing tubeless tires in automotive industry. However, product is majorly used as a fuel and lubricant additive to improve the overall performance owing to its highly reactive nature compared to conventional polyisobutylene which will make significant contribution to highly reactive polyisobutylene market size in the coming years.

Highly Reactive Polyisobutylene Market Share

Major highly reactive polyisobutylene market share contributors are:

- TPC Group

- RB Products, Inc

- BASF SE

- PETRONAS

- Janex

- Lanxess

- Kothari Petrochemicals

- Mayzo.

- Jinzhou Snda Chemical

- Ningbo Hi-Tech Biochemicals

- Shanghai Minglan Chemical

- Jinzhou Snda Chemical

- Weifang Binhai Petro-chem

- Shandong Hongrui New Material Technology

Most of these players have been engaged in expanding their production capacity to meet rapidly rising consumer demand and to attain competitive advantage. For instance, TPC Group announced capacity expansion of polyisobutylene unit in February 2015. It was intended to strengthen their position in North America.

Industry Background

Highly reactive polyisobutylene is comparatively more reactive than conventional polyisobutylene due to the position of double bonds in the terminal position of the molecule which make it react more quickly specially as fuel and lubricant additive. It is a commercial polymer which possesses thermal stability, good flexibility and impermeability to gases. In addition, it has high resistance to acids, alkalis and salts. It is majorly used in the manufacture of inner tubes of tires, adhesives, sealants in construction industry, serum vials, injectables, saline bottles, seals for medical packaging and chewing gum among others.

Rapidly growing automotive industry due to amplified consumer spending power in Asia Pacific is a major factor contributing to highly reactive polyisobutylene market size during the forecast period. Additionally, growing construction industry in Asia Pacific and MEA is another factor likely to make significant contribution to the industry share owing to its wide-ranging applications as adhesives and sealants which will drive highly reactive polyisobutylene market size by 2024.

Highly reactive polyisobutylene market research report includes in-depth coverage of the industry, with estimates & forecast in terms of volume in kilo tons and revenue in USD million from 2013 to 2024, for the following segments:

By Molecular weight

- Low

- Medium

- High

By Application

- Automotive

- Additive

- Others

The above information is provided on a regional and country basis for the following:

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Spain

- Italy

- Asia Pacific

- China

- India

- Japan

- Australia

- Indonesia

- Malaysia

- Latin America

- Brazil

- Mexico

- Middle East & Africa

- South Africa

- GCC

Frequently Asked Question(FAQ) :

Why is highly reactive market observing robust expansion in Middle East?

Middle East will register a CAGR of over 7% through 2024 due to increasing product demand driven by the thriving construction industry in the region.

Why is highly reactive polyisobutylene witnessing higher demand in additive application?

Additive application segment will observe a CAGR of around 5% through 2024 owing to the product

How will highly reactive polyisobutylene market fare across North America?

North America will observe a CAGR of over 4.5% through 2024 with increasing product demand from construction, automotive and medical packaging industry.

How will highly reactive polyisobutylene market perform through 2024?

Highly reactive polyisobutylene market size is anticipated to reach CAGR of 4.7% through 2024 owing to rising environmental concerns.

Highly Reactive Polyisobutylene Market Scope

Related Reports