Home > Chemicals & Materials > Polymers > Industrial Polymers > Ethylene Propylene Diene Monomer (EPDM) Market

Ethylene Propylene Diene Monomer (EPDM) Market Size

- Report ID: GMI738

- Published Date: Aug 2016

- Report Format: PDF

Ethylene Propylene Diene Monomer Market Size

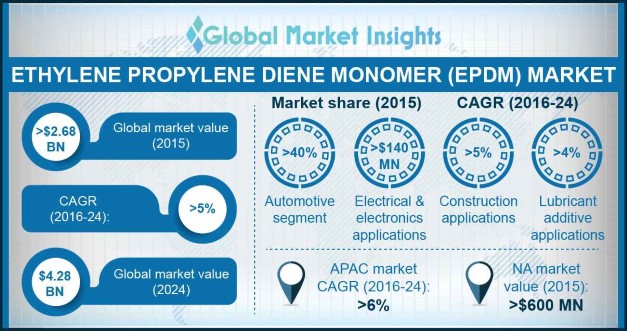

Ethylene Propylene Diene Monomer (EPDM) Market size was valued over $2.68 billion in 2015 and is expected to witness a CAGR of 5% through 2024. The industry is mainly driven by growing automotive and construction sector. Asia Pacific was largest regional market in 2015 owing to the expansion of end use industries particularly in China and India.

Growing automotive industry, accompanied with increasing range of applications within the domain is anticipated to propel the market growth over the forecast timeframe. Global commercial and personal vehicle production was over 220 billion units & 680 billion units respectively in 2015. Rapid automotive sales in the coming years are anticipated to complement growth.

Also, increasing per capita spending results in drifting consumer focus towards functional as well as luxurious cars is another factor likely to propel the ethylene propylene diene monomer.

Plastic plays a vital role in various end user industries. It is one of the major raw materials used in plastic modification application, and is primarily employed in the polymer modification process for olefinic thermoplastic elastomers such as thermoplastic olefin (TPO) and thermoplastic vulcanizates (TPV).

| Report Attribute | Details |

|---|---|

| Base Year: | 2015 |

| Ethylene Propylene Diene Monomer Market Size in 2015: | 2.68 Billion (USD) |

| Forecast Period: | 2016 to 2024 |

| Forecast Period 2016 to 2024 CAGR: | 5% |

| 2024 Value Projection: | 4.28 Billion (USD) |

| Historical Data for: | 2013 to 2015 |

| No. of Pages: | 82 |

| Tables, Charts & Figures: | 99 |

| Segments covered: | Application and Region |

| Growth Drivers: |

|

| Pitfalls & Challenges: |

|

Global thermoplastic olefin sector was more than 950 kilo tons in 2015 and is projected to surpass 1500 kilo tons by 2024. TPVs are polymeric compounds that demonstrate elastomeric properties over a wide temperature range and thermoplastic behavior at the melt temperature.

In addition, TPV is used in a wide range of automotive applications primarily due to its excellent UV and ozone resistance, low part weight; and high chemical and weathering resistance. It is employed in under-the-hood applications, tubing, air ducts, suspension bellows, plugs, molded seals, and cable jacketing.

TPO is an olefinic elastomer that typically consists of thermoplastic, elastomer, and filler. It is used in the range of 5% to 20% in the formulation of TPOs. Increasing polymer application in end user industries such as automotive and construction will positively influence ethylene propylene diene monomer market from 2016 to 2024.

Construction industry in Asia Pacific, particularly led by China, India, and Japan, is witnessing gains and is likely grow exponentially in the near future. China construction spending was over USD 1.7 trillion in 2015. Increasing polymer use in construction for roofing purposes will drive the EPDM market up to 2024.

Significant capacity addition by major industry players has resulted in product oversupply, which may hamper EPDM market price. Also, the global synthetic rubber market has been witnessing a change in the demand-supply dynamics. This is likely to further negatively influence industry growth.

The market is also influenced by oscillating crude oil prices as raw materials used in manufacturing process are petroleum products, making the outcome non-biodegradable. However, introduction of bio-based EPDM products with sugarcane and other bio based raw materials is anticipated to boost growth.