Home > Chemicals & Materials > Specialty Chemicals > Chemical Indicator Inks Market

Chemical Indicator Inks Market Size

- Report ID: GMI769

- Published Date: Sep 2016

- Report Format: PDF

Chemical Indicator Inks Market Size

Chemical Indicator Inks Market size was valued at over USD 35 million in 2015 and is forecast to experience gains exceeding 7% up to 2024./p>

Global chemical indicator inks market is primarily driven by robust product demand in surgical instrument market. Sterilization processes are predominantly used in surgical instruments, as they remain in direct contact with the patient during the surgical procedure. Global surgical instrument market generated revenue over USD 5.5 billion in 2015. Increasing usage of disinfection and sterilization procedures in surgical applications to prevent hospital associated infections will drive market growth in the near future./p>

Nosocomial infections and their control is a global challenge considering the high morbidity and mortality of patients. Additionally, nosocomial infections increase the expenses on health care due to added antimicrobial treatment and prolonged hospitalization. Furthermore, high expenditure on healthcare in APAC countries including China, Japan and India will consequently propel global chemical indicator inks market demand by 2024./p>

| Report Attribute | Details |

|---|---|

| Base Year: | 2015 |

| Chemical Indicator Inks Market Size in 2015: | 35 Million (USD) |

| Forecast Period: | 2016 to 2024 |

| Forecast Period 2016 to 2024 CAGR: | 7% |

| 2024 Value Projection: | 78.35 Million (USD) |

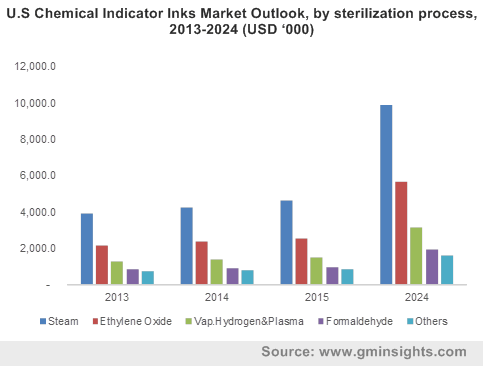

| Historical Data for: | 2013 to 2015 |

| No. of Pages: | 150 |

| Tables, Charts & Figures: | 285 |

| Segments covered: | Sterilization Process, Printing Process, Product, Application and Region |

| Growth Drivers: |

|

| Pitfalls & Challenges: |

|

Food & beverages are one of the major segments of the global packaging market. Canned food market such as fish, meat, and other perishable foods, is expanding, as canned food offers increased shelf life along with advantages such as retention of flavors of packed food. In addition, global rigid packaging market was marked at over USD 150 billion in 2015. This will ultimately boost chemical indicator inks market share.

These products are used in flexographic and rotogravure printing processes primarily consist of four components: solvent, resins, colorants, and additives. These are fluidic in nature majorly due to petrochemicals use as solvents. These solvents dry in ambient air, releasing a significant amount of volatile organic compounds, which are environmentally harmful. However, bio-based chemical indicator inks which includes naturally available materials instead of petroleum-based materials as solvents has created new industry growth opportunities.

Challenging formulation process is significantly affected by the printing process selected. For instance, the flexographic printing process is fluidic than that used for screen printing, which increases the overall cost owing to negatively influence chemical indicator inks price market trends.