Home > Industrial Machinery > Industrial Equipment > Assembly Machine Market

Assembly Machine Market Size

- Report ID: GMI4287

- Published Date: Aug 2019

- Report Format: PDF

Assembly Machine Market Size

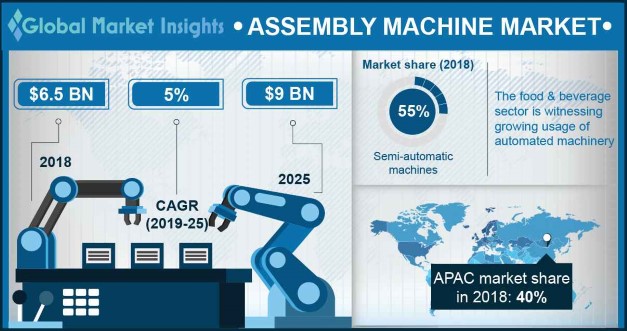

Assembly Machine Market size valued at over USD 6.5 billion in 2018 and will grow at a CAGR of more than 5% from 2019 to 2025.

Ongoing technological advancements in industries, such as automotive, healthcare, and electronics, are compelling manufacturers to automate solutions and increase productivity in production lines, driving the assembly machine market growth. The equipment is being widely used in assembling small & intricate components that require precision and care throughout the manufacturing process. The rising demand to improve the product quality by eliminating errors and reducing variability in several industrial applications will drive the industry growth over the coming years. Semi-automatic & fully automatic machines are enabling businesses to handle multiple tasks to meet specific requirements. The adoption of automated assembly systems will provide a safer work environment to workers and reduce the occurrence of failures.

| Report Attribute | Details |

|---|---|

| Base Year: | 2018 |

| Assembly Machine Market Size in 2018: | 6.5 Billion (USD) |

| Forecast Period: | 2019 to 2025 |

| Forecast Period 2019 to 2025 CAGR: | 5% |

| 2025 Value Projection: | 9 Billion (USD) |

| Historical Data for: | 2014 to 2018 |

| No. of Pages: | 150 |

| Tables, Charts & Figures: | 130 |

| Segments covered: | Type, Application and Region |

| Growth Drivers: |

|

| Pitfalls & Challenges: |

|

The growing adoption of assembly units to develop medical devices, such as syringes, catheters, inhalers, and disposables, will drive the market demand. The pharmaceutical industry is using plastics over metal, aluminum, and bronze to maximize equipment efficiency. Plastics offer a wide range of properties such as low friction, lightweight, self-lubricating, chemical & corrosion resistance, better wear properties, noise abatement, and high strength, reducing the downtime and increasing the production efficiency. Pharmaceutical industries are implementing automated machinery to process, assemble, test, inspect, and package these parts. Several manufacturers are integrating advanced technology into machinery to offer reliable, precise, and durable operations. For instance, Orientech Automation integrated FANUC robots and products for high-speed assembly of syringes, vials or test tubes for pharmaceutical and medical sectors.