Summary

Table of Content

Assembly Machine Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Assembly Machine Market Size

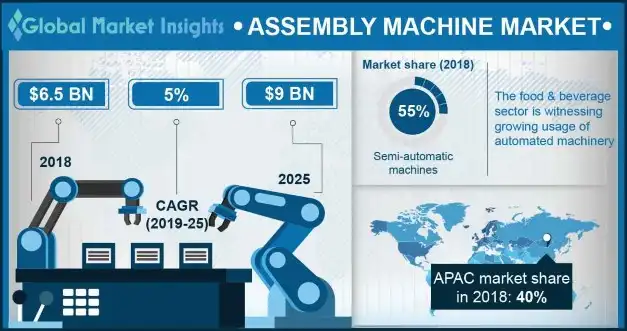

Assembly Machine Market size valued at over USD 6.5 billion in 2018 and will grow at a CAGR of more than 5% from 2019 to 2025.

To get key market trends

To get key market trends

Ongoing technological advancements in industries, such as automotive, healthcare, and electronics, are compelling manufacturers to automate solutions and increase productivity in production lines, driving the assembly machine market growth. The equipment is being widely used in assembling small & intricate components that require precision and care throughout the manufacturing process. The rising demand to improve the product quality by eliminating errors and reducing variability in several industrial applications will drive the industry growth over the coming years. Semi-automatic & fully automatic machines are enabling businesses to handle multiple tasks to meet specific requirements. The adoption of automated assembly systems will provide a safer work environment to workers and reduce the occurrence of failures.

Assembly Machine Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2018 |

| Market Size in 2018 | 6.5 Billion (USD) |

| Forecast Period 2019 - 2025 CAGR | 5% |

| Market Size in 2025 | 9 Billion (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

The growing adoption of assembly units to develop medical devices, such as syringes, catheters, inhalers, and disposables, will drive the market demand. The pharmaceutical industry is using plastics over metal, aluminum, and bronze to maximize equipment efficiency. Plastics offer a wide range of properties such as low friction, lightweight, self-lubricating, chemical & corrosion resistance, better wear properties, noise abatement, and high strength, reducing the downtime and increasing the production efficiency. Pharmaceutical industries are implementing automated machinery to process, assemble, test, inspect, and package these parts. Several manufacturers are integrating advanced technology into machinery to offer reliable, precise, and durable operations. For instance, Orientech Automation integrated FANUC robots and products for high-speed assembly of syringes, vials or test tubes for pharmaceutical and medical sectors.

Assembly Machine Market Analysis

Learn more about the key segments shaping this market

Learn more about the key segments shaping this market

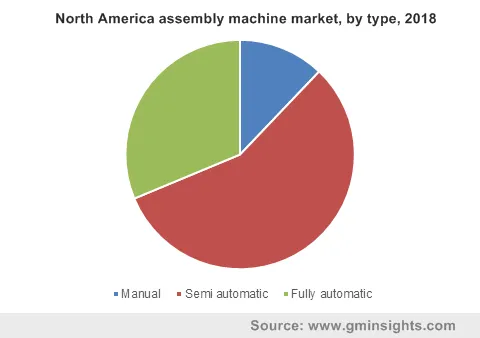

In 2018, semi-automatic machines accounted for over 55% of the assembly machine market share and are being adopted by businesses to improve the quality and labor productivity as manual assembly machines are time-consuming. They are operated partly automatically and partly manually for loading & unloading the entire system in the manufacturing process. Small and Medium Enterprises (SME) are highly implementing these machines to cut their operational costs, enhancing productivity in manufacturing processes. Moreover, these machines are integrated with robots, palletized conveyor lines & automated feeders, and require less human interaction for loading & unloading of parts in each step of the assembly process. Businesses having less production and high-quality manufacturing prefer these machines to improve the production process while retaining the adaptability of operator’s input.

The food & beverage sector is witnessing growing usage of automated machinery. Changing customer preferences on consumable products, rising consumer income, the adoption of western culture in several countries, and transformation of the retail trade sector are resulting in higher consumption of food & beverage products. Manufacturers are adopting the equipment for the manufacturing of sports drink dispensing closures, syrup delivery valves, and plastic bottles. These machines are helping businesses to speed up the production process. Moreover, suppliers are offering machines for the assembly of specific components. For instance, RNA Automation Limited is providing cap assembly machines to efficiently feed, orient, and assemble the push-pull cap. These machines can be connected to other machines in production lines, enabling quick & automatic feeding, filling, assembly, capping, and discharging of finished products, increasing the productivity.

Learn more about the key segments shaping this market

Learn more about the key segments shaping this market

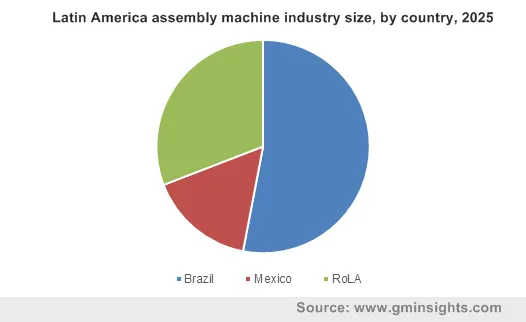

Increasing government initiatives and support to improve economic conditions in countries, such as Brazil, Mexico, and Argentina, will drive the adoption of automated solutions in the Latin American market. According to the World Bank’s Enterprise Surveys, 31.6% of companies have inadequately trained workers. Lack of skilled workers is forcing industries to invest in technologies, such as Industry 4.0. The rise in government and organization initiatives for improving the manufacturing sector will provide lucrative growth benefits to the assembly machine market. For instance, organizations under Brazil's National Confederation of Industry (CNI), announced their plan to invest in automation for the manufacturing of goods. The rise in the manufacturing sector coupled with the growing need for efficiency and quality in manufacturing processes continues to drive the Latin American market growth. Food, beverages, healthcare, and pharmaceutical industries are major deployers of machinery in the Latin American region. Several consumers are importing their machinery from countries including the U.S., Germany, and Italy.

Assembly Machine Market Share

The industry is diversified in nature, with major players differing based on the product offering. Some key players in the assembly machine market are

- A UNO TEC S.R.L.

- Bystronic Maschinen AG

- EMAG GmbH & Co. KG

- Extol, Inc.

- FANUC Corporation

- Gefit Group

- Haumiller

- Hindustan Automation

- Humard Automation SA

- Intec Automation, Inc.

- Isthmus Engineering

- Kawasaki Heavy Industries, Ltd.

- Mondragon Assembly

- Norwalt Design Inc.

- RNA Automation Limited

among several regional & international players. Manufacturers are increasing investments for automation to differentiate their product offerings and gain a competitive advantage. Companies are expanding their business operations in various parts of the country to increase the customer base and expand their market presence. In February 2018, Haumiller Engineering announced the opening of its new corporate and engineering facility in South Elgin, Illinois, and the U.S. The new facility will allow the company to expand its manufacturing and production capacity of assembly machines.

Industry Background

Manufacturers in the industry are integrating advanced technologies to differentiate their products from competitors. Some of the major players are developing machinery based on industrial demand. They are also focusing on developing solutions as per the specific needs of customers. For instance, Norwalt Design, Inc., is offering customized machines, which enable the assembly of two or more components and incorporate additional features such as ultrasonic welding, leak testing, vision systems, filling, and heat sealing. Similarly, TQC Ltd., has designed machines for processing plastic components with an automatic insert placement operation, enabling simple quality control function. Moreover, the threat of new entrants is moderate due to high initial investments & costs associated with R&D activities. The strong presence of global players is pressuring new entrants to provide highly reliable & efficient products, making it difficult for them to enter.

Frequently Asked Question(FAQ) :

Which region will witness an increased deployment of assembly machines?

Latin America assembly machine industry will grow on account of favorable government initiatives to improve industrial and economic conditions in countries including Brazil, Argentina, and Mexico.

What are some of the key factors driving the adoption of semi-automatic assembly machines?

SMEs having less production and high-quality manufacturing are increasingly deploying semi-automatic assembly machines to cut operation costs and enhance productivity in manufacturing processes.

How much did the global assembly machine market size account for in 2018?

The market size of assembly machine was valued at over USD 6.5 billion in 2018.

How much growth will the assembly machine industry share witness during the forecast timeframe?

The industry share of assembly machine will grow at a CAGR of more than 5% from 2019 to 2025.

How are ongoing technological advances enhancing assembly machine market share?

Ongoing technological developments in automotive, electronics and healthcare sectors and growing need for automation to boost productivity is fueling assembly machine deployment.

Why are assembly machines increasingly being installed across food & beverage applications?

The growing need to enhance product quality by reducing errors and variability in industrial operations is accelerating the adoption of assembly machines.

Assembly Machine Market Scope

Related Reports