Summary

Table of Content

Aluminum Alloys Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Aluminum Alloys Market Size

Aluminum Alloys Market size was registered at over $100 billion by 2016 gaining the industry by CAGR over 5% from 2017 to 2024. Rising global tourism and corresponding demand for air, water, as well as land transportation and increasing demand for superior means of commuting in order to meet the needs for the growing industrialization will further augment the industry growth.

To get key market trends

Worldwide automotive sales crossed 90 million units in 2016 from less than 80 million units in 2011, growing considerably after the economic slowdown of the previous decade. Majority of the passenger car sales were concentrated in the Asia Pacific region owing to the rapidly increasing GDP and purchase power of the population of China, India, and Japan. Increasing demand for light weight alloys for enhancing the vehicle performance and efficiency will have a positive influence on the aluminum alloys market in coming years.

Asia Pacific GDP growth was recorded at more than 5% in 2014, of which manufacturing contributed for a significant chunk. Overall industrial developments in China, India, South Korea, Japan, and Indonesia will play a major role in the global market in coming years. Availability of cost-efficient workforce accompanied with lenient industrial norms have invited several manufacturing conglomerates to shift their manufacturing bases in this region. Wide range of industrial application of the product including die casting, manufacturing machineries and equipment will have a positive impact on the aluminum alloys market share.

Aluminum Alloys Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2016 |

| Market Size in 2016 | 100 Billion (USD) |

| Forecast Period 2017 - 2024 CAGR | 5% |

| Market Size in 2024 | 150 Billion (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

Poorly regulated bauxite mining in the straits of Malaysia and Indonesia has created several concerns regarding the ecological impact. Rise of respiratory and skin diseases due to exposure to mining dusts may pose threats to the aluminum alloys market as aluminum is procured from these ores. In the European Union bauxite mining is governed by a European Innovation Partnership (EIP) body named Bauxite Residue and Aluminium Valorisation Operations (BRAVO) which focuses on improving the aluminum value chain and secondary raw material recovery.

Aluminum Alloys Market Analysis

On the basis of product, it is segmented into wrought alloy and cast alloy. Wrought alloy has higher tensile strength in cast alloys and has more aluminum content, making it a popularly used product category. It is lighter in weight and is normally free from common casting defects such as porosity and shrink. With increasing demand for lighter and stronger metal for fabrication of different mechanical parts, global aluminum alloys market segment will witness substantial gain in coming years.

Cast alloys are manufactured with other elements including silicon, copper, magnesium, zinc, and tin, in order to provide the required characteristics for specific applications. For instance, aluminum-tin alloy exhibits low strength but extremely high wear resistance, while aluminum-copper alloys have high strength and low corrosion resistance. Specialty engineering for development of specifically required mechanical parts will have a positive influence on the global cast aluminum alloys market.

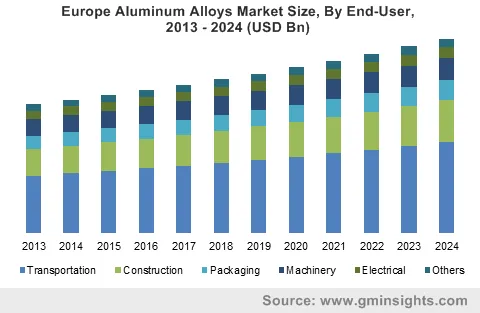

Transportation industry is the most significant end-user industry and will hold sway the aluminum alloys market, both in term of volume and revenue throughout the forecast span. Increasing demand for light weight automobiles and aircrafts to enhance the fuel efficiency will drive the product application in this industry in coming years. Transportation industry accounted for more than 45% share of the global market in 2016 and will exhibit growth at more than 5.5% CAGR through 2024.

Learn more about the key segments shaping this market

Construction sector registered more than USD 20 billion in 2016. Increasing urbanization all over the globe and requirement of shelters for the continuously increasing population will augment the aluminum alloys market growth in the coming years. Light weight and strength gives them superiority over iron and steel products used in the construction sector.

Asia Pacific accounted for more than 60% of the global share in 2016 and will witness growth by a CAGR more than 5.5% in the forecast years. Aggressive developments in the construction, automotive, and marine industry in China will signify the regional industry growth in the next few years. Growing industrialization in India and Southeast Asian countries will further augment the aluminum alloys market sales.

Presence of several high-end automotive and aeronautical companies in Europe, especially in Germany, UK, France, and Italy, will positively influence the regional market in coming years. Technologically advanced manufacturing units are primarily driven by increasing the product efficiencies. Aluminum alloys market demand in these countries will grow on the account of increasing demand for performance products in the end-user industries.

Aluminum Alloys Market Share

Aluminum alloys industry competitive landscape is moderately fragmented with the top four manufacturing companies, namely

- United Company RUSAL Plc

- Rio Tinto Alcan

- Aluminum Corporation of China Ltd.

- Alcoa Inc.

accounting for more than a quarter of the global share in 2016. Other key industry players include

- Kobe Steel Ltd.

- Constellium

- Aleris International Inc.

- Aluminium Bahrain B.S.C.

- Dubai Aluminium Company Ltd.

- Norsk Hydro ASA

- Kaiser Aluminum Corporation

The aluminum alloys market ecosystem has a considerable amount of backward integration as major manufacturers try to secure the bauxite sources for product consistency. The companies also strengthen their market hold with continuous R&D effort for product development along with strategic acquisitions and mergers. For instance, Kaiser Aluminum acquired Alexco LLC in 2011 to expand their product portfolio for the aerospace sector.

Aluminum alloys Industry is highly dependent on the availability of bauxite ore for the extraction of aluminum. The market participants rely on a strong supply chain to maintain the continuous supply of the raw material as well as distribute the product to various end-user industries. Owing to a wide range of application, aluminum alloys industry demand will witness a noteworthy growth in the coming years.

Aluminum alloys market report includes in-depth coverage of the industry with estimates & forecast in terms of volume in kilo tons & revenue in USD million from 2013 to 2024, for the following segments:

By Product

- Wrought alloy

- Cast alloy

By End User Industry

- Transportation

- Construction

- Packaging

- Machinery

- Electrical

- Others

The above information is provided on a regional and country basis for the following:

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Spain

- Italy

- Asia Pacific

- China

- India

- Japan

- Australia

- Indonesia

- Malaysia

- Latin America

- Brazil

- Mexico

- MEA

- South Africa

- GCC

Frequently Asked Question(FAQ) :

How much growth is the aluminum alloys industry projected to record over the forecast spell?

The aluminum alloys market is likely to register a crcr of 5% over the forecast period.

How much valuation is the aluminum alloys market predicted to record in the year 2024?

In 2024, the aluminum alloys industry is estimated to record a valuation of 150 Billion (USD).

Aluminum Alloys Market Scope

Related Reports