Home > Professional Services > 3D Printing in Automotive Market

3D Printing in Automotive Market Size

- Report ID: GMI2838

- Published Date: Aug 2018

- Report Format: PDF

3D Printing in Automotive Market Size

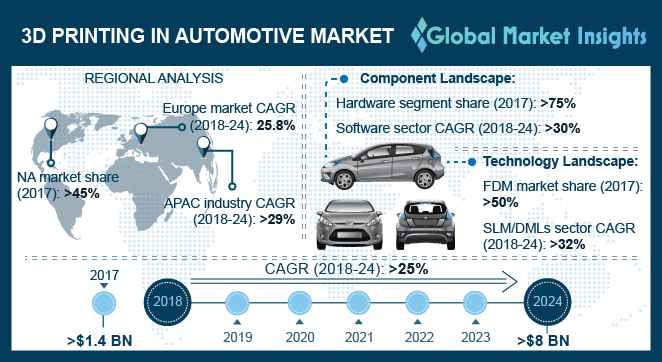

3D Printing in Automotive Market size was estimated to be over USD 1.4 billion in 2017 with the annual sales of over 110 thousand 3D printers. The market is anticipated to grow at a CAGR of more than 25% over the forecast timespan.

The 3D printing in automotive market is propelled by the growing requirements in the automotive sector for cost-effective and efficient technology to develop high-quality and complex products. The technology has enabled the development of products, which were technically not feasible earlier with the traditional methods. The building mechanism of the additive manufacturing technology allows the freedom of design and enables the integration of internal components under previously inaccessible surfaces or parts. Furthermore, it enables manufacturers to combine parts for integrated functionality that will improve the performance and durability of the product while keeping the cost low.

The decline in the price of the 3D printers is augmenting their demand in the market. The technological advancement and fueling competition among the 3D printing in automotive market players to cater to the demand for the desktop printers are responsible for the decline in the prices of 3D printers. Earlier, the 3D printers were bifurcated into two categories, desktop printers costing below USD 5,000 and industrial printers costing over USD 5,000. However, over the past five years, the price brackets have changed significantly. The desktop printers are now priced as low as USD 700. This is encouraging the use of 3D printers in organizations.

| Report Attribute | Details |

|---|---|

| Base Year: | 2017 |

| 3D Printing in Automotive Market Size in 2017: | 1.4 Billion (USD) |

| Forecast Period: | 2018 to 2024 |

| Forecast Period 2018 to 2024 CAGR: | 25% |

| 2024 Value Projection: | 8 Billion (USD) |

| Historical Data for: | 2013 to 2017 |

| No. of Pages: | 280 |

| Tables, Charts & Figures: | 477 |

| Segments covered: | Component, Technology, Application and Region |

| Growth Drivers: |

|

| Pitfalls & Challenges: |

|

However, the limited build envelope of the existing additive manufacturing technology is the major restraint in 3D printing in automotive market. The technology is being primarily used to manufacture smaller parts due to the limitations in the powder bed diffusion technology used in metal printing. In addition, economies and scalability issues associated with the technology are also hindering the market growth.